Site contractors have a three-fold objective for each project:

- Produce a quality product.

- Finish the job on time.

- Don’t lose profit.

Difficult to do, but possible if unexpected problems do not arise. And you can bet that problems will arise. So what can you do to address such problems without delays, costly expenses and second rate work? In this the first of three articles, we will examine how to use polymers to reduce surface soil erosion.

Let’s look at a common situation: It is Friday afternoon, and your crews have left early for the weekend. You look outside of your trailer to see a big stockpile of unprotected soil on the edge of the work area.

You are pleased that an adjoining, pristine creek has not been disturbed, but the weather report on your cell phone shows a thunderstorm headed your way before nightfall. What are you going to do? It is too late to phone for rescue by outside subcontractors, and they are already busy on another site — not your site.

You don’t have a potential problem — you have a real problem right now. However, if you have remembered the old Boy Scout motto, “Be Prepared,” and stocked the right materials for your “rainy day,” you can protect the creek and the jobsite.

Sizing Up a Problem

Some construction sites do not have erosion problems. They are the sites that have porous, sandy soils that can be addressed with mechanical practices such as sediment barriers (silt fences), berms or diversion ditches and filter dams.

Other sites have a lot of clay in the soil. They have all the problems because clay-sized particles do not respond to mechanical or physical barriers. These cohesive soils do not provide good infiltration and thus promote surface runoff and erosion. The alternative for these clay soils is to use chemical practices offered by companies that specialize in using specific products. If they are not available, is there something you can do?

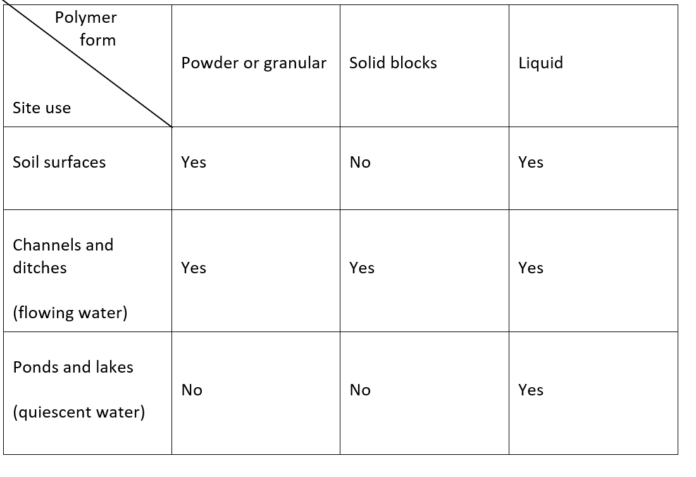

Yes, you can do it yourself, perhaps not perfectly, but enough to reduce the erosive problem until more help arrives on Monday. Maintaining a supply of erosion control polymer products can save time and money spent cleaning up the eroded stockpile of soil after the storm. Preparation includes researching polymer properties to know which products match best with your site conditions (Figure 1).

Powder Polymer on Soil Surfaces

Hydrated polymers can create a micro-thin protective layer on the soil surface to reduce particle detachment by rainfall impact. Particles attached by polymers do not flow readily across the soil surface. For the most effective coverage, apply polymers from the bottom and the top of a slope.

- For small areas, a portable fertilizer spreader can be used (Figure 2). Proper clothing and protection is highly recommended to avoid skin and breathing problems. A retreating route is best for spreading powder polymer by hand on non-windy days.

- For moderate-sized areas, a funnel attached ahead of the trigger of a powered leaf blower is a good technique (Figure 3). To push the flour-like polymer a further distance, one portion of polymer should be premixed with four parts of dry sand. Be sure to create a venturi notch in the orifice of the funnel to prevent blow back of the polymer/sand into your face. Normally, this is a two-person technique. One loads the funnel with the powder/sand mix, and the operator triggers the blower tube toward the area to be covered (Figure 4).

Liquid Polymer on Soil Surfaces

Manual application is time-consuming for very large areas and steep slopes. Liquid polymers are more commonly used separately or incorporated into hydroseeding applications (Figure 5). A secondary benefit is that the polymer will tack the seed in place until it germinates. If you attempt this technique, be sure to add the powder slowly into the circulating water in the tank. It will not dissolve if you dump it all at once. A wet application can be applied to reduce dust problems, especially on the shoulders

of roads.

[Editor’s Note: This is the first article in a series of three that address the use of polymers for erosion control on jobsites. The next two articles will discuss polymer applications for ditches and channels and for quiescent ponds.]

About the Expert

James W. Spotts, M.S., Ph.D., CPSS, CPESC, is president of Southeast Environmental Consultant LLC. His company provides site inspections and NPDES discharge monitoring in the regional Atlanta area. Also known as “Dr. Dirt,” Spotts is passionate about sharing practical knowledge and teaching others how to solve field problems through demonstrations and class involvement.