The Oregon Department of Transportation (ODOT) FFO-US20 PME Phase 3 project located in Eddyville, Oregon was one of many phases of the 5.5 miles (8.8 km) rural stretch of US Highway 20 that improved the existing, dangerous two-lane highway by constructing a new four-lane divided highway. The project area receives more than 100 inches (2,540 mm) of rainfall annually and laid entirely within the drainage area of the Yaquina River. Because of these unique site features and due to past environmental impacts during the design-build phase in 2006, achieving environmental compliance was of the utmost importance. Phase 3 comprised of two seasons where approximately 2.5 million cubic yards (1.9 m3) of earth and rock were excavated and placed to construct the new roadway section.

The original slope stabilization plan for the fill slopes after each season included straw wattles used as slope interrupters, a flexible growth medium for surface mulching and an erosion control seed mix in order to stabilize the slopes. During the 2014 Phase 3 season one winter, many of the straw wattles that were trenched into newly placed fill slopes did not perform as well as was intended. The seed mix was effective in some areas, but not in others. The root system of the seed mix did not have enough time to establish and extend deep enough into the soil to prevent surficial failures on the steeper slopes.

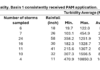

Data

Throughout several winter storms, numerous surficial slope failures in many areas on the project occurred after permanent slope stabilization measures were installed. These types of failures are shallow and usually parallel to the slope face with a depth of 4 feet (1.2 m) or less. The failures seen on the project were not due to poor management of water on top of the fill slopes but were failures starting in the middle of the slope, many originating at wattle locations. Many shallow slope failures occur when the rainfall intensity is larger than the soil infiltration rate, and the rainfall lasts long enough to saturate the slope up to a certain depth, which leads to the buildup of pore water pressure. Given the frequency of rain events in Eddyville, the project received a continuous wetting of the slope, which saturated the wattles. There was no evidence of increased sediment build up blocking flowthrough. Once fully saturated, water pooled behind them, exceeding the infiltration rate of the soil and creating shallow surficial slope failures.

BMP Installation

Once a shallow failure occurred, ODOT and the contractor agreed that installing erosion control blanket (ECB) C32 BD (100% biodegradable double net and 100% coconut fiber), over the affected area would serve as a better BMP for slope stabilization. This method has shown to work very well on other projects, keeping the slope from eroding any further and preventing additional failures. To further prevent erosion and runoff, the wattles were removed (Figure 1), sediment buildup was cleared, rills were fixed, the slope was track walked and re-seeded (Figure 2) and ECB was installed over the affected area (Figure 3).

Season Two Constructability

During the second construction season of Phase 3 it was decided to replace wattles with ECB where embankments were built with primarily native non-durable rock. During season one of the Phase 3 construction season, embankments built with this material were very difficult to track walk before installing wattles. Attempting to track walk on top of these rock slopes caused dozers to slip or spin their tracks, which damaged the surface of the slope. Another challenge with installing wattles on non-durable rock slopes is the actual installation itself. Straw wattles are often specified to be trenched into the slope, potentially causing other issues associated with wattles performance. Trenches need to be perfectly straight and the entire wattle row needs to be at the same elevation. To do this, laborers use hand tools to dig a small trench and install the wattles. Digging these trenches on the surface of a slope built out of compacted non-durable rock is close to impossible. We saw a few isolated examples of this exact scenario in 2014, and the results were not good. Laborers struggled to dig the trenches, and the trenches that they were able to dig did not follow ground contours because they had to route trenches around larger rock fragments that they were unable to trench through.

Discussion

Over the two construction seasons of Phase 3, approximately 2.5 million cubic yards (1.9 cubic meters) of material was excavated and placed. The first season provided a great understanding about which BMPs worked best for slope stabilization on the new fills and which did not. Although wattles are proven to reduce the velocity and spread the flow of rill and sheet runoff, they were not the most effective erosion control BMP for the extreme slopes on this specific project.

Moving forward with that knowledge, the slope stabilization plan for the second season was changed. Straw wattles on the fill slopes were omitted and ECB C32 BD was used in conjunction with the flexible growth medium and seed (Figure 4). The growth medium, seed and matting was a great combination for erosion protection. The hydraulic erosion control product required no cure time to be effective. This was a great benefit for the project because it was constantly wet.

Once the second season of construction was complete and permanent slope stabilization BMPs installed, it was evident that many of the difficulties described within this article with straw wattle installation were eliminated. The slopes did not have to be track walked, and the ECB only needed to be trenched into the ground at the very top of the slope. One of the primary concerns with ECB is obtaining constant, continual contact with the slope. If the ECB is installed on a smooth engineered slope with staples every 2 feet on center, there should not be issues maintaining continual ground contact. Even with the uneven surface on the slopes built with native non-durable rock, the ECB was installed with fairly good contact with the soil and still functioned very well. Environmental compliance was achieved throughout Phase 3, due largely in part to the revised slope stabilization plan.

About the Expert

Tiffany Nibler, MPH, CPESC, has specialized in environmental compliance in the construction industry throughout the Western United States for over 12 years. She currently manages the environmental sector for Scarsella Brothers Inc., a heavy civil construction company working with federal, state and local municipalities, ports and railroads as well as commercial developers and engineers,