The Town of Big Flats, New York had a challenging series of stormwater channels on a public right-of-way. The series of stormwater channels transported rainwater and snowmelt that originated from a steep hill, crossed rights-of-way and eventually emptied into a stream. The long downhill run caused concentrated flows in the channels that temporary rolled erosion control products (RECPs) could not withstand. The decision was made to protect the land from erosion and scour by investing in a comprehensive overhaul of the failing stormwater channel system.

No modern best management practices (BMPs) were used in the original channel design, so property damage and maintenance problems occurred with each large rainfall and snowmelt event. Extensive soil erosion in the channels was an eyesore, and during large rain events, stormwater volume exceeded the containment capacity of the existing channels. To complicate matters, upstream channels that crossed private property were altered for aesthetic purposes over the years. These alterations significantly reduced the system’s ability to slow the water velocity entering the lower channels. The existing stormwater channels were lined with rip rap and had eroded swales approximately 4 feet (1.2 m) wide and 24 inches (61 cm) deep (Figure 1). A successful stormwater control plan using modern BMPs was needed to reduce the chance of damage to nearby properties.

Design Solutions

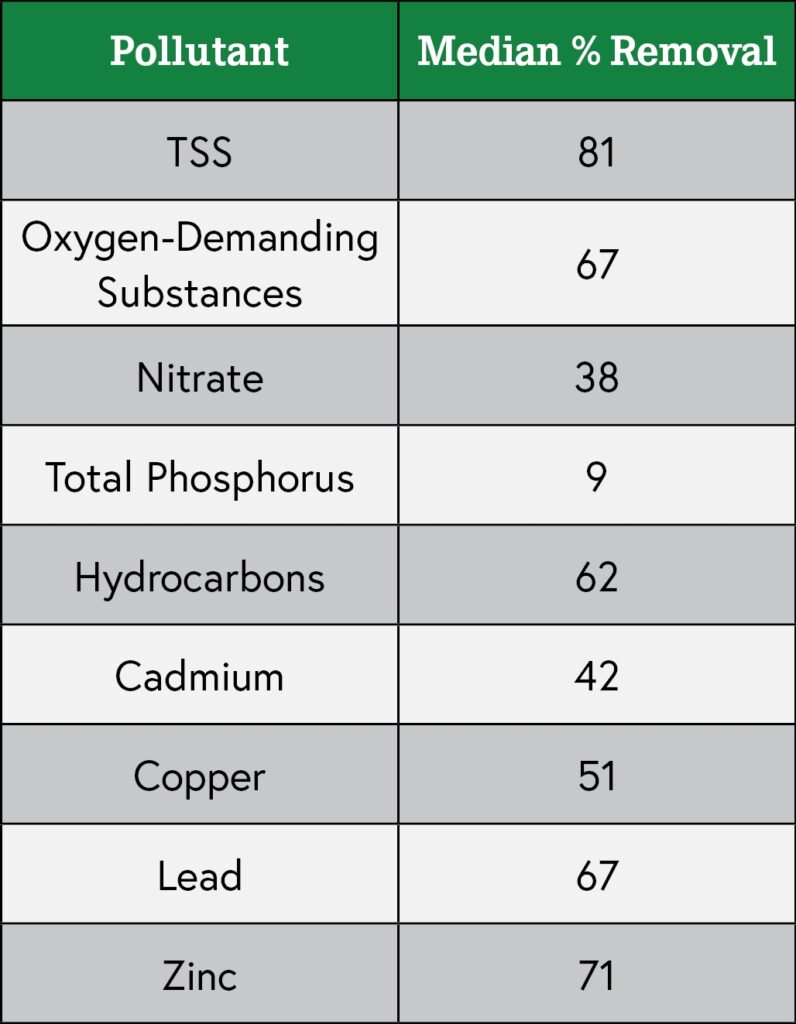

The benefits of vegetated channels or swales vs. riprap include improved contaminant filtration (Figure 2), flow velocity reduction, improved site access, lower carbon footprint and less destructive installations. For these reasons, engineers decided to use a vegetated channel solution that would carry runoff from the site and prevent the formation of gullies that deposit sediment further downstream. To do so, they incorporated several channel BMPs, including heavy-duty turf reinforcement mats (TRMs), scour protection mats, rock check dams and sediment retention ponds. Erosion control blankets (ECBs) were installed outside the main channels to protect the soil from erosion during rain and wind events and encourage vegetation growth.

Once final engineering and design solutions were approved for the site, the contractor began by implementing erosion and sediment control improvements. The contractor chose two American Excelsior products: a three-netted, fully synthetic TRM to line the stormwater channels and a straw ECB to line the sediment retention pond and protect other areas outside the channels.

As the first line of defense that covered most of the channel’s soil surface area, the TRM needed to be able to withstand whatever erosive forces it could potentially encounter.

Bound by three ultra-heavy-duty UV stabilized polypropylene nets, its matrix consists of 100% post-consumer recycled polyester fibers. Eighty percent of these fibers are greater than 5 inches (13 cm) in length, and all retain 95% memory of their original shape after loading via hydraulic events. Additionally, the fibers’ specific gravity is greater than 1.0, which means they do not float during hydraulic events. These characteristics allow the TRM to maintain its structural integrity and minimize erosive potential at the channel’s surface.

Scour protection mats were installed along with the TRMs to protect the outflows of stormwater culverts from plunge scour. Together, they worked to protect soil at such highly concentrated flow points from eroding and moving down the channel. Rock check dams were used to reduce flow velocity and consequently aid in vegetation establishment in the channel. Lastly, sediment retention ponds were strategically located to collect stormwater at the site.

Executing the Plan

Existing channels were excavated, and the existing rock channel bottom was removed. The channels were then reshaped, deepened and widened to create more stormwater capacity and promote stormwater infiltration. After excavation was complete, the channels were compacted and fine-graded to remove any rills. The contractor ensured that the channel was free of obstructions such as tree roots, large rocks and other foreign objects, then evenly distributed topsoil at a depth of 4 inches (10 cm) to prepare for seeding.

After the channels were repaired and reshaped, they were seeded and fertilized. A cover crop of grain rye was applied at 20.0 lb/ac (22.4 kg/ha) and the specified upland low-growing wildflower-and-grass mix was applied at 30.0 lb/ac (33.6 kg/ha). After seeding was completed, the swales were lined with the three-netted TRM, and new rock check dams were installed on top of the TRM. Bare soil side slopes were seeded, fertilized and covered with straw ECBs (Figure 3).

Results

The design team recognized that the shear stress capability of vegetation alone would not survive the design flows of the channel. Therefore, the installation of the three-netted fully synthetic TRM was critical to successfully protecting the channel. It reinforced the newly established vegetation in the channel, allowing it to withstand future high-stress events and carry runoff away from the site. Coupled with scour protection mats at the culvert outflows, rock check dams, and sediment retention ponds downstream, the vegetated channel solution provided and continues to provide long-term protection for the site and surrounding area.

Meanwhile, the straw ECBs protected the soil that was disturbed outside the channels during construction. The resulting vegetation reduced the sediment load flowing to the newly established channels.

In total, more than 6,500 square yards (5,400 square meters) of the three-netted TRM and 3,000 square yards (2,500 square meters) of the straw ECB were used on the complex, ecologically sensitive 2-mile- (3-kilometer-) long project (Figure 4).

Lessons Learned

To meet the needs of the modern-day job site, it is imperative that professional project teams look for innovative solutions that, in most cases, will be a combination of multiple BMPs. Project team professionals must identify risks and understand the cost of failure. Every project, large or small, comes with a responsibility to find solutions that work to improve the environment. Modern BMPs, like the ones used on this project, allow for sites to be returned to natural conditions. They are better for water and wildlife and at the same time strong enough to protect our infrastructure.

Reference

Storm Water Technology Fact Sheet: Vegetated Swales. United States Environmental Protection Agency. Washington D.C. September 1999. Page 4.

About the Expert

Harvey Dickson, CPESC is employed by American Excelsior Company – Earth Science Division – Arlington, TX, as a territory manager of the Mid-Atlantic, New England, and Eastern Canada regions. He has over 16 years of experience in the erosion and sediment control industry and is vice president of the Northeast IECA chapter.