Stormwater runoff is a leading source of water quality impairment in the United States. The most common pollutants carried by stormwater include sediment, pathogens, nutrients and metals. These pollutants are often found in runoff from construction sites and urban and agricultural lands. The goals of the Clean Water Act, established 52 years ago, remain unmet as current best management practices struggle to keep pace.

Phase I

In July 2023, Fagan Consulting LLC and Auburn University received a Phase I contract with the U.S. Department of Transportation (DOT) through the DOT’s Small Business Innovation Research (SBIR) program to develop a self-contained portable stormwater treatment device. Over the following six months, the Fagan-Auburn team worked to demonstrate the innovation’s technical merit, feasibility and commercial potential. The project later received a non-dilutive supplemental grant from Innovate Alabama that deemed the team’s proposed approach “viable, valuable and scalable.” Innovate Alabama, a public-private partnership, promotes entrepreneurship, technology and innovation across the state.

By early 2024, the team had developed and tested a working lab-scale prototype, secured provisional patent protection and developed an initial commercialization and marketing plan. Supplemental funding from Innovate Alabama enabled the team to develop a full-scale working prototype and continue research and development beyond the goals of the SBIR contract.

The innovative device uses electrical flocculation, or electroflocculation, to bind up pollutant particles suspended in stormwater runoff. This method is based on the established application of electrocoagulation techniques used in water and wastewater treatment. Electrical flocculation works by passing electric current across metal plates as water flows between. The current causes positively and negatively charged ions to be released into the polluted water. The ions bind with pollutant particles with opposite charges to form larger particles. Accelerated settling and removal of these electrically neutral bound particles, or flocs, takes place as their size and density increases. This process is similar to chemical flocculation but eliminates the need for chemical polymers or other reagents.

The treatment device, called an electric floc generator, operates using a 12-volt solar-powered renewable energy source. It functions as self-contained and portable or as installed at a fixed location with an external power source. While direct current is the primary operating current type, alternating current can be accommodated using a power converter.

In terms of size and portability, the original full-scale prototype has a rectangular shape with a replaceable electrode cartridge in the center of the device. The housing for the initial floc generator (Figure 1) prototype was 3D-printed and is approximately 8 inches x 8 inches x 19 inches (20.3 cm x 20.3 cm x 48.3 cm). It weighs less than 15 pounds (6.8 kg). This model was designed to be connected to a sediment basin surface outlet structure with in-line mixing and floc settling downgradient. The device is easily transported using the built in handle.

The team has initially focused on addressing TSS and turbidity with the floc generator. Construction stormwater runoff was the first target due to sediment being one of the more difficult stormwater pollutants to treat, and because of the Fagan-Auburn team’s extensive past work and expertise in managing construction stormwater. Initial testing showed that the turbidity of “treated” construction stormwater (after pretreatment using a sediment basin and surface outlet structure) was reduced by over 70%.

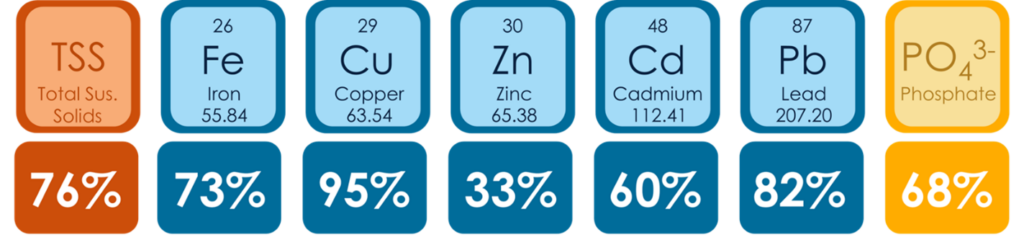

The floc generator can be easily adjusted to remove a range of pollutants from stormwater runoff in both construction and post-construction environments. It can also be scaled to treat larger flows or pollutant loads. Preliminary large-scale testing has shown effective reductions in total suspended solids, metals and nutrients (Figure 2). Preliminary spectrophotometry tests revealed that, even under worst-case scenarios, dissolved aluminum concentrations in water treated with the floc generator were below drinking water standards. As the device reaches the final stages of prototyping, additional toxicity tests, including bioassays, will be performed to ensure all toxicity concerns are thoroughly addressed.

Phase II

The Fagan-Auburn team recently received a two-year Phase II contract from the U.S. DOT and secured another round of supplemental funding from Innovate Alabama. The objectives of Phase II include continued research and development, product demonstration and delivery to the commercial market.

Future research and development will be driven by established product specification goals. Goal areas include safety, portability, installation, operation and maintenance, modularity and expandability, ruggedness, automation and remote monitoring, pollutant types and loading, and flow rate accommodation.

The next generation of the floc generator will have the ability to float inside a sediment basin or detention pond and pull water through itself for treatment. Mixing will take place inside the device, and settling will take place in the basin or pond. This model is nicknamed “Tiger Shark” and will optimize the space, shape and availability of a PVC pipe as the housing (Figure 3). In-line prototypes will be further optimized and evaluated for discharge occurring into a vegetated buffer or swale. Additional configurations will be developed in Phase II to adapt to various construction and post-construction applications.

Crowdsourcing

Members of the Fagan-Auburn team have developed a network of stormwater professionals and contacts as they have demonstrated the floc generator to a variety of audiences including Clear Water Alabama Conference and Installer Training and Field Day Events at Auburn University (Figure 4). The team is hoping to leverage ideas presented by the stormwater community to discover new application possibilities and for assistance with demonstration and field-testing sites. The team is also interested in learning about general concerns related to the concept of electrical flocculation in stormwater treatment and encourages people to reach out to the authors to learn more or offer suggestions.

About the Experts

- Barry Fagan, PE/PLS, ENV SP, CPESC, CPMSM, is the principal investigator for the floc generator development project and co-owner of Fagan Consulting LLC.

- Megan Armstrong, EI, is an engineering intern with Fagan Consulting LLC and a Ph.D. student at Auburn University. Her research on the project will serve as her Ph.D. thesis.

- Michael A. Perez, Ph.D., CPESC, is an associate professor in the Department of Civil and Environmental Engineering at Auburn University.