Communities across the nation are faced with growing pressures to better address the persistent challenge of urban stormwater. Permeable pavement was developed to overcome this fundamental challenge by mimicking natural infiltration processes. However, rapid clogging of first-generation permeable pavements limited performance by preventing water from reaching the stone bases. In response to the clogging challenge, regulatory agencies have limited applications, imposed engineering redundancies and restricted crediting for permeable pavement.

Permeable articulating concrete block (P-ACB) pavements are next-generation permeable surfaces, developed by adapting an erosion control system into the pavement. P-ACB systems differ from traditional permeable pavers because they have open joints and use their large, interlocking pattern to handle heavy traffic loads. The open joints of this system allow it to handle more rainwater and make it easier to maintain because the cleaning process is required less frequently and is easier to perform. The suitability to handle heavy traffic loads enables P-ACBs to be used in all applications like roadways, traffic aisles and truck stops.

Case Studies

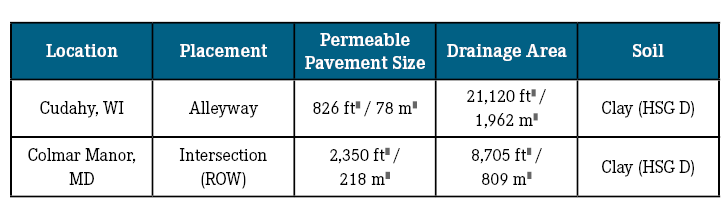

The use of P-ACBs in two locations has proven to effectively handle stormwater and reduce the maintenance needs of the pavement.

Colmar Manor, Maryland, USA is located in a low-lying area with a high degree of impervious cover, poor drainage and pluvial flooding. The Maryland Department of Transportation approved using the PaveDrain P-ACB system in the public right-of-way for an asphalt traffic intersection that faced frequent stormwater challenges (Figure 1).

The State of Maryland’s guidance manual does not permit run-on or the use of permeable pavement on D (clay) soil. Because the town was familiar with the P-ACB product, the municipality accepted responsibility for the performance and maintenance of the site to allow for its construction. The as-designed drainage area was expected to be 8,705 feet2 (809 m2) but was found to be 10% larger: 9,400 feet2 (873 m2). Third-party soil testing was conducted during construction showing the presence of A (high infiltrating soil), B and D soils.

In Cudahy, Wisconsin, USA, the PaveDrain P-ACB product is installed in a shared alleyway. The system is sized to fit inside the wheel path of traditional garbage collection vehicles to minimize truck traffic loading (Figure 3). The city requested this design although it is not necessary for systems rated to HS-25.

Wisconsin Department of Natural Resources (WDNR) limits run-on to 5:1 (permeable pavements may not drain more than five times their surface area). The actual run-on area was approximately 25 times the permeable surface constructed in the alley. The extreme run-on area was a perfect opportunity to use a P-ACB system given its very high surface infiltration rates. At this site, clay (D) soil was found during preliminary site investigations and the system design assumed very poor exfiltration characteristics. This resulted in the system using a relatively deep, 3-feet (91-cm) storage gallery and a 6-inch (15-cm) diameter underdrain kept just off the bottom of the gallery, open and draining to the downstream inlet structure.

Both locations use in-situ real-time sensors (Figure 4). The sensors were installed in the aggregate storage galleries to measure water levels. At each location, the water level sensor is accompanied by a nearby weather station (Figure 5) monitoring rainfall, temperature, barometric pressure and relative humidity. During a storm, water enters the base quickly and exfiltrates from the stone base into the subgrade over time. Sensors document the movement of water to verify the system’s performance. All underdrains were converted hydraulically to overdrains by adding vertical standpipes at discharge locations thereby raising discharge elevations. No overflow events were observed during the measurement periods.

Observed Performance

At both sites, the systems captured all run-on and infiltrated almost all of the rainfall events within 48 hours. Fully capturing and infiltrating rainfall removes all nitrogen, phosphorous and total suspended solids that are mobilized over the drainage area.

Data from the Cudahy site was analyzed by P4 Infrastructure staff and presented to WDNR who accepted their findings.1,2 The Colmar Manor site was studied by the University of Maryland as an independent third party.3

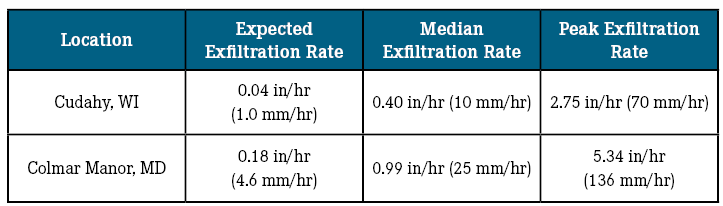

The median exfiltration rates over 48 hours exceeded expected rates by 5x–10x (Figure 6). The peak exfiltration rates with high hydrostatic head pressure exceeded 5 inches per hour, which exceeded expectations. The average exfiltration rate over the first 48 hours is 0.99 inches (2.51 cm) per hour. For most jurisdictions, stormwater designs would expect clay soil to infiltrate at 0.18 inches (0.46 cm) per hour or less, nearly a full order of magnitude less than the rates measured in the field.

The discrepancy between observed and expected values is attributable to the heterogeneous nature of the soil and hydrostatic head. While clay soil is present, so are more permeable soils that form three-dimensional networks and paths for water to exit the stone base, which leads to elevated performance. Academically-determined data with a homogenous soil does not reflect real conditions over large surface areas. The peak infiltration rates are provided to help elucidate the effect of hydrostatic head.

In the three years since it was installed in Colmar Manor, the system has been functioning as a roadway and stormwater BMP without maintenance, which represents a commitment to environmental justice in this economically disadvantaged neighborhood.

Crediting and Use of Verified Data

Because of the additional credit provided by these single BMPs and verified by the sensors, both jurisdictions sought and were provided real credit for their site above their relevant design manual. The Wisconsin site showed that BMP area footprints can be reduced by up to 88% when using P-ACB systems with instrumentation.

Prince George’s County took credit for the sensor-verified environmental site design value of 1504 feet3 (42.6 m3) versus the guidance manual value of 376 ft3 (10.6 m3).

Conclusion

Designing BMPs that have substantially delayed clogging cycles allows the infiltration process to proceed. In some cases, design manuals have applied overly conservative engineering design factors to permeable pavements that have failed to account for the development of innovative systems. Sensor systems have shown a clear difference between desktop-modeled design and field-measured performance in the next generation of permeable pavement, and they should be incorporated until regulations are able to reflect real performance.

References

- Weik T. 2021. Green Infrastructure Planning and Implementation Recommendations within the Total Daily Maximum Load Watershed. CBC Engineers.

- Diekfuss J, Foley C. 2022. Permeable Pavement Systems Clean Water Faster and for Less Money. P4 Infrastructure.

- Butters S, Davis AP. 2023. Evaluating Performance of PaveDrain Permeable Pavements in Colmar Manor, MD. University of Maryland.

About the Experts

- Aaron Fisher, Ph.D., PMP, receive his doctorate in chemical engineering from the University of Maryland and a bachelor’s degree in chemistry from Duke University. He is the vice president of business development at Ernest Maier.

- Joseph Diekfuss, Ph.D., PE, is a civil engineer with 15 years of experience. He is co-founder and vice president of P4 Infrastructure. He is a licensed Professional Engineer in Wisconsin, USA, a National Highway Institute Certified Bridge Inspector and first-named inventor on three United States patents in the area of civil engineering.