Although innovation is often defined as a new idea or product, it can also be used to describe finding a new use for an existing product. The unlikely story of how an oil spill absorbent became an effective control for stormwater pollution in Australia and the United States is a perfect example.

Repurposing Textile Waste

Every year, 92 million tons of textile waste is produced globally.1 To put that figure into perspective, this weight is the equivalent of 250 Empire State Buildings. Textile waste is a growing issue that’s facing increased significance, and one United States-based company has found a unique way to help tackle the textile waste problem. Halen Hardy specialises in spill control products and has developed a production method that takes old clothes, furniture and bedding, then breaks them down to base fibres. These fibres are then heat pressed to convert them into an absorbent media known as Spilltration Husky.

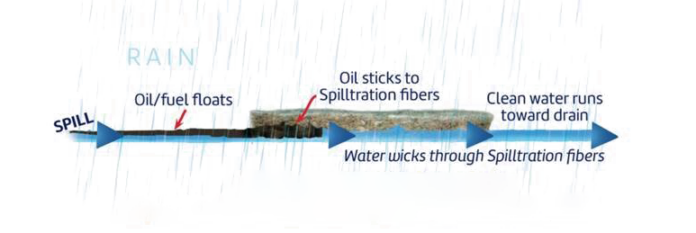

This recycled absorbent media has some impressive characteristics. First and foremost, it absorbs hydrocarbons. While water is absorbed, it is not retained by the material. These unique characteristics have made the absorbent media popular for use in traffic emergency response because oil and fuel spills can be absorbed while rainwater filters through the media (Figure 1). The ability to filter water is maintained, even when saturated by oil.

Utility for Sediment Filtration

A secondary benefit was discovered after the recycled absorbent media’s popular use as an oil spill absorbent. It was found that the absorbent could also be used to become a filter to trap sediment in addition to hydrocarbons.

To quantify its performance, the absorbent’s filtration performance was tested by an independent laboratory. A series of tests showed conclusively the material had the ability to effectively trap particles as small as 53 microns (0.053mm). For reference, particles of this size are finer than the average human hair.

The absorbent media’s unique construction plays a key role in its filtration ability. Fibres are bonded and heat pressed without the use of additives, and this composition enables water to be drawn into and wick through, helping to maintain filtration in sediment control applications.

Adding Durability for Long Term Usage

The recycled absorbent media showed promise for stormwater protection as a drain filter, however, improving its durability to withstand long-term foot and vehicle traffic presented a design challenge.

In its standard form, the recycled absorbent would result in piling and eventual disintegration when exposed to prolonged and direct contact. Extensive testing showed that these effects could be mitigated by adding a protective outside layer to prevent lateral movement of the absorbent media.

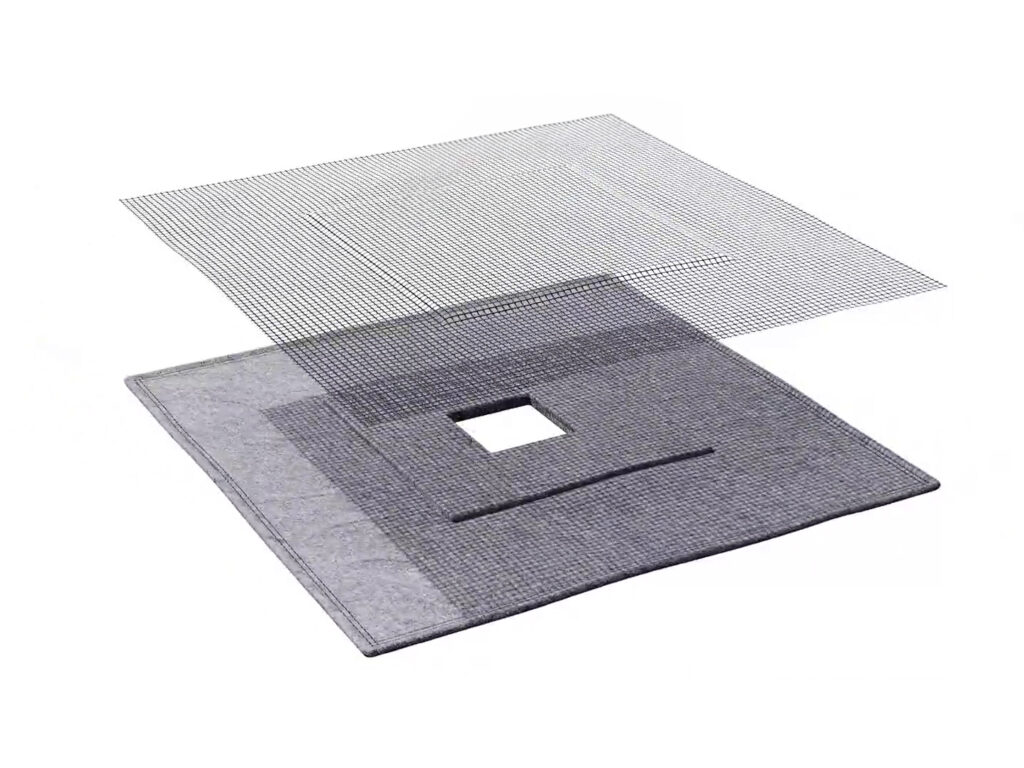

Polyurethane mesh was chosen to protect the absorbent media because of its UV resistance and inherent durability. The mesh is sewn directly to the absorbent media (Figure 2), with eyelets for added strength and to secure the drain filter in place once installed.

For maximum effectiveness in installation the drain filter is positioned over stormwater drains with a slight overhang. It is compatible with box, v-grate and side inlet stormwater drain types. Drain filters also feature a raised center section, which helps to create a damming effect to further improve the capture of sediment during heavy rain. Additionally, an overflow port helps to prevent water from backing up in heavy rain events. For side inlet stormwater drain systems, inbuilt aluminum strips are utilised to achieve a tight fit around curbs. The filter can be cleaned using a hose from behind to further extend its lifespan.

Real-world Applications

Construction sites, rail yards, car parks and gas, energy and manufacturing facilities are common risk areas for stormwater pollution that can benefit from the installation of a drain filter. In Australia and New Zealand, the drain filter is known as the GuardDog Drain Filter. In 2021, it was verified by the Innovation Sustainability Council as an Australia-first innovation for use on a major freeway upgrade (Figure 3). Since then, it has been used on countless construction projects. In the United States and Canada, the drain filter is known as the HuskyGuard. It has been specified as best management practice on major class 1 railroads and for the construction of a major petrochemical plant in Pennsylvania.

Benefits over Traditional Solutions

Aside from the sustainability benefits, the drain filter presents multiple advantages over traditional sediment control methods such as silt socks and drain pollution guards. The drain filter features a low-profile design, which improves safety for pedestrians and cyclists. Silt socks are also susceptible to splitting as they age or when driven over. This can result in debris spilling on the road and into stormwater drains.

Drain filters installed over stormwater drains make the prospect of an overloaded drain cavity unlikely. Moreover, time spent maintaining and cleaning filters is less than that of in-drain alternatives, as litter and debris can be swept away by hand or streetsweeper.

Moving Towards Sustainable Partnerships

Pollution prevention solutions such as the drain filter highlight the value of sustainable partnerships. Such partnerships extend beyond a conventional business relationship, due to a shared commitment towards environmental challenges. This synergy helps to bridge the gap between environmental responsibility and innovative solutions, resulting in a win-win for the stakeholders involved.

The relationships with end users who are seeking a fit-for-purpose solutions with additional sustainability benefits are very important. The value proposition of a stormwater pollution control device does not relate to the drain filter itself but to the journey towards jointly-crafted solutions that optimize performance, efficiency and environmental impact.

Reference

- Ellen MacArthur Foundation. A new textiles economy: Redesigning fashion’s future (2017).

About the Expert

Martin Brown is the marketing manager at Stratex, an Australian leader in environmental and personal protection solutions. He specialises in marketing and digital transformation and has worked with many of the world’s leading organizations in technology, healthcare, hospitality and safety.