In most areas, stormwater basins or ponds are the most common means of stormwater management. Basins have a proven history of being a cost-effective means of reducing the peak rate of discharge for developments to mimic pre-development conditions. Within the past 20 to 30 years, post-construction water quality has become just as important, if not more so, than quantity control, and methods of using basins to provide water quality have also begun to be implemented.

Traditional First-Flush Methodology

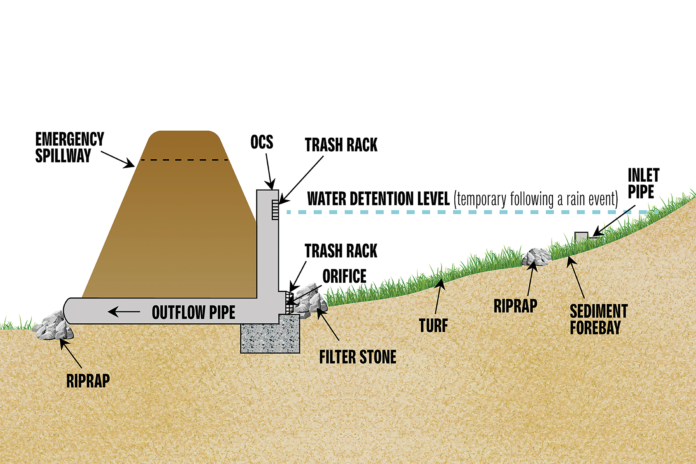

The most common method of providing water quality with a stormwater basin is the first-flush model. The first-flush model attempts to capture a standard runoff volume from the area draining to the pond and then slowly release that volume with the intent of allowing sediment and other pollutant particles to settle to the bottom of the basin before being discharged. The first-flush volume requirements vary from state to state but are generally 1 to 1.5 inches (2.5 to 4 cm) of runoff from the contributing area when draining to a dry detention or extended detention basin (Figure 1) and typically half of this volume when draining to a wet retention or extended wetland-type basin.

While the first-flush methods are widely accepted, there are several flaws with this design. One flaw is the release rate for the first-flush. It typically assumes that the entire first-flush volume instantaneously appears in the basin and is then drained over a specified time period, typically 24 hours. This is unrealistic as the pond will actually fill up over time as rainfall accumulates. This fallacy results in ponds being designed with a significantly larger volume than is actually utilized during a storm event that generates the first-flush volume of runoff.

Another flaw is that this methodology relies upon settlement created by ponding to achieve water quality. During small storm events, there is generally very little ponding as the flow will exit the pond nearly as quickly as it enters. Since the water quality is dependent upon settlement time, this results in very little to no treatment of small storm events, particularly in dry basins.

Finally, the discharge point for dry basins is generally located at the bottom of the pond, which is where the design concentrates sediment and other pollutants. Although a trash guard to minimize clogging should be part of the design, this does little to keep fine sediment particles and other pollutants from being discharged, especially when there is minimal ponding time or resuspension in a subsequent rain event.

Use of Floating Outlets

Floating outlets, also known as skimmers, have become the standard for sediment basins during construction and are widely recognized as significantly improving the trapping efficiency of the basin to greater than 80% of total suspended solids (TSS). However, skimmers are typically removed once construction is complete, and the ponds revert to a low-flow orifice to release the first-flush volume. One reason for this is that many skimmers are constructed of PVC. Because PVC is not UV-resistant and will weather, crack or break after a few years in the basin, it is not considered acceptable for permanent use. If skimmers were available that could be considered for permanent use, they could be a good option to function as the low-flow orifice, which would improve the TSS removal efficiency of basins.

Development of Skimmer Filter

Over the past five years, Rymar Waterworks Innovations has been researching the use of skimmers to help meet post-construction water quality requirements. During the research, the concept of adding filters around the skimmer to provide cost-effective treatment of stormwater runoff was evaluated. The research involved the development of several prototypes and testing them in existing basins as well as controlled test tanks. It became apparent that the biggest challenge was to develop a filter that would provide adequate treatment and maintain the flow rate of the skimmer.

The initial prototypes use filtration media that fit closely to the skimmer and fully encapsulated the skimmer to ensure all flow went through the filter. Although the filter media had been tested to confirm flow rates, the force created by the skimmer to pull the flow through the media was insufficient, and the filters became the limiting factors. Many different types of filters were tested but a suitable media could not be identified.

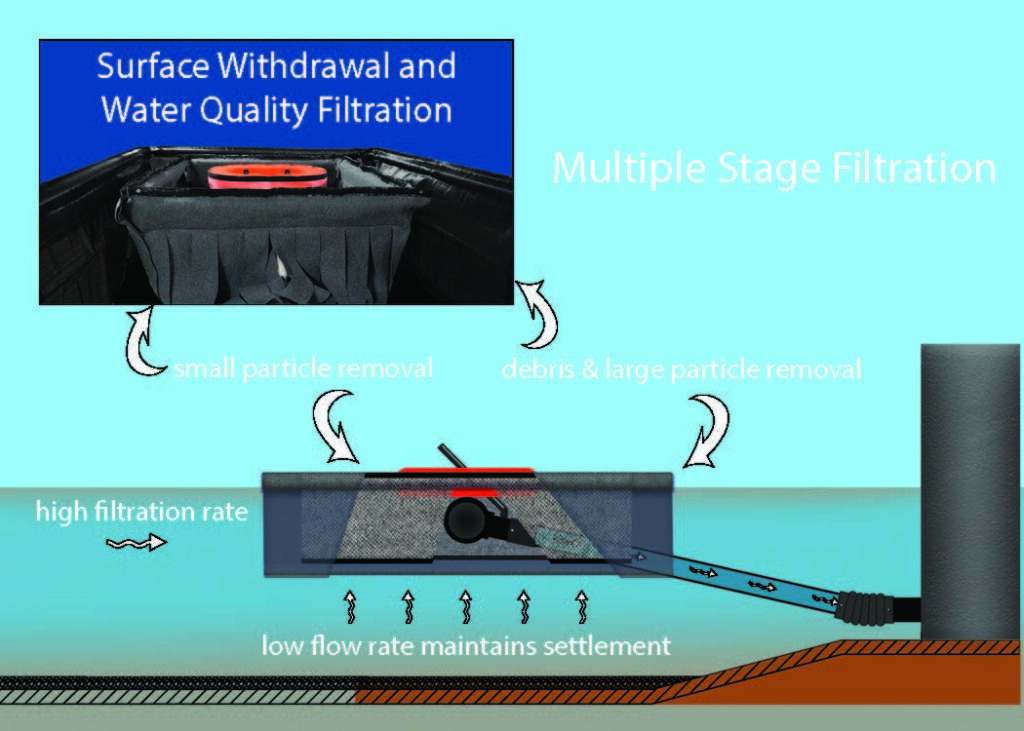

Eventually, a larger filter that included a two-stage system was developed (Figure 2). The outer stage of the filter was constructed from a woven polyethylene filter fabric, which acted as a screen to remove debris and larger sediment particles. The inner filter was constructed of a non-woven geotextile with two layers of fabric. Slits were cut in each layer of fabric at 6-inch (15-cm) intervals, with the slits offset in the two layers. This facilitates flow through the fabric and increases contact time with the fabric to aid in the capture of fine particles and potentially dissolved particles. Both filters were constructed to have a 3-foot (0.9-m) depth from the water surface, which uses settlement/gravity to prevent sediment or pollutant particles from being discharged through the skimmer as the force of flow under the filter is not sufficient to pull the particles up 3 feet (0.9 m) to be discharged by the skimmer.

This prototype was placed in an existing basin and closely monitored for over two years. Although no sampling was done during this time, the discharge from the skimmer/filter system was noticeably less turbid than water in the basin. A time-lapse camera was installed to monitor the system during storm events and confirm the draw-down times remained consistent even after the filters began to accumulate substantial debris and sediment.

After two years of monitoring, the system was tested by TRI Environmental in accordance with ASTM C1746 for Sediment Retention devices to confirm the TSS removal efficiency. The testing involved running the sampling on two versions of the system with the flow rate of one being more than double the flow rate of the other. The testing included verification of the flow rate during the test. The test tank was set up to simulate a dry basin. The sediment-laden water was introduced within 2 feet (0.6 m) of the outer filter, which was done intentionally to remove any benefit of a typical forebay and travel distance that would be associated with a typical stormwater basin. The intent was to show the filter could meet water quality requirements without the other typical features of a pond so there was confidence that when placed in a pond, the performance would be equal or better than the lab testing results.

The results of the testing found that both versions of the skimmer with filter achieved greater than 90% TSS removal efficiency. The final version of the water quality filter has been installed in the test pond and continues to be monitored to confirm performance and verify lifespan of the filter materials (Figures 3 and 4).

Benefits of Pond Filtration

Based upon the field research and third-party laboratory confirmation, the skimmer with filter combination can be an excellent choice to aid in meeting post-construction water quality requirements in stormwater basins with several significant advantages over the traditional first-flush method. These include:

- The skimmer may be sized to be the quantity control orifice for smaller storm events such as the two-year 24-hour storm, which is often the lowest regulated peak flow event.

- The skimmer/filter combination will treat 100% of the runoff up to the peak storm managed by the skimmer flow. This results in the treatment of very small storm events as well as much larger storm events than what would generate the first-flush volume. Therefore, more of the annual rainfall is treated and treated to a higher level than the traditional first-flush method.

- The first-flush water quality volume can be released faster since it is not relying on settlement and is instead treated by the filter. Because the excess storage is not needed to slowly release the first-flush volume and the hydrology model can be accurately run to utilize the actual volume required to attenuate the regulated storm events, this results in a reduction of pond sizes by 15% or more.

Challenges with Filters in Ponds

As with any best management practice (BMP), there are some challenges to be aware of when considering using filters in basins.

Like all BMPs, maintenance of the filters needs to be considered. Based upon monitoring of prototypes, the filters would be expected to last at least two years, however, that would be impacted by the amount of sediment and debris in the basins. They may need to be cleaned by brushing away accumulated sediment and debris occasionally if they appear to become clogged. During prototype testing this was not necessary even though the pond used for the prototype testing receives a large amount of trash and debris in the stormwater runoff on a regular basis. As previously discussed, the skimmer should also be durable and expected to last for 20± years or planned to be replaced on a regular basis.

In areas that experience significant freezing, the filters may not be the best choice or at a minimum may need an alternative way to drain the pond, such as a perforated riser with a valve. Note that the filters have not been tested in areas other than very mild frozen conditions for short periods of time.

Possibly the biggest current challenge to the use of filtration in ponds is that there are very few areas with established standards to allow this type of design. Many areas do have standards for how to include manufactured treatment devices or proprietary devices as BMPs and these can often be applied to the use of filtration in basins.

There have been many advancements in practices and products to aid in achieving water quality requirements for stormwater in the past thirty years. It is important to remember that water quality has only been required in most of the country since 1990 for Phase I MS4s and 2003 for Phase II MS4s. As water quality becomes more of a focus and additional standards are recognized through ASTM and other national organizations, it should be expected that the industry will continue to evolve and provide more options to aid in keeping our most important resource clean.

About the Expert

Jamie McCutchen, PE, is principal and founder of Rymar Waterworks Innovations, which makes the Marlee Float Skimmer and Rymar Water Quality Filter. He has over 30 years of civil engineering and land development experience and is licensed South Carolina, North Carolina and Georgia, USA.