Early erosion control focused on modifying agricultural practices and plantings, such as kudzu. Early construction erosion and sediment control techniques focused on hay bales and silt fence while modifying the agriculture practices developed by the USDA Soil Conservation Service (formerly the Erosion Control Service, now the Natural Resource Conservation Service).

The industry has continued to grow and adopt many new and improved products to help keep soil in its place and to trap sediment before it leaves the site. Unfortunately, some of these products can be hazardous to some wildlife.

My first experience with rolled erosion control products (RECPs) was a project in Maine around 1997. I received a phone call from the Maine Department of Environmental Protect stating that the site looked good except that there were several songbirds stuck in the erosion control blanket. We were asked to visit the site and remove all the RECPs. The impact of RECPs on wildlife has been recognized and written about for years.1, 2, 3, 4

Regulations

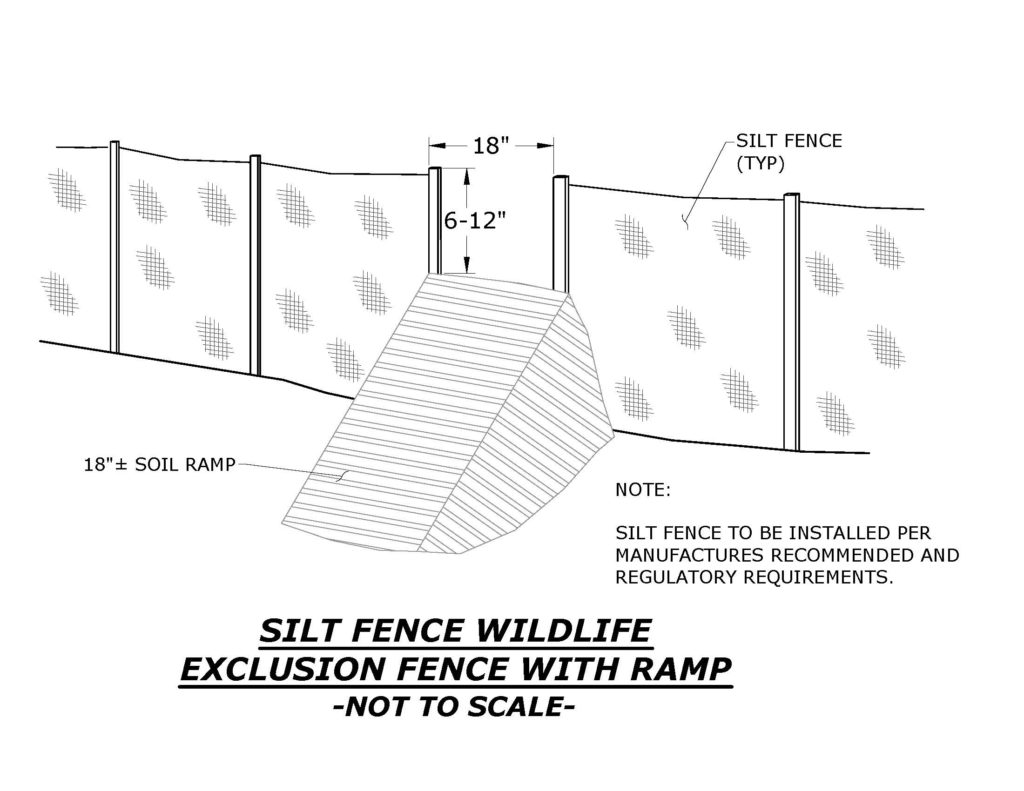

Both federal and state agencies focus on wildlife-friendly stormwater regulations. The U.S. Fish and Wildlife Service provides recommendations and specific rules are being adopted by states across the country from California to Indiana and Minnesota to Vermont.5 Many of these focus on types of RECPs that are allowed to be used. In New Hampshire, mostly due to a recent court case,6 the New Hampshire Fish and Game Department is providing input to New Hampshire Department of Environmental Services on wildlife-friendly materials to use in stormwater design. In Massachusetts, where endangered turtles were found in the vicinity of an airport project, not only were the turtles radio tracked during the construction, but the silt fence and construction entrances were modified to prevent turtles getting in, and if they did, providing a means for them to escape. Turtles traveling to and along the silt fence encountered a ramp that took them outside the construction site (Figure 1). In both of these states, a major component of the permitting and construction is to train the contractor on how to identify the species of concern and what to do if the animal is found (Figure 2).

Rolled Erosion Control Products

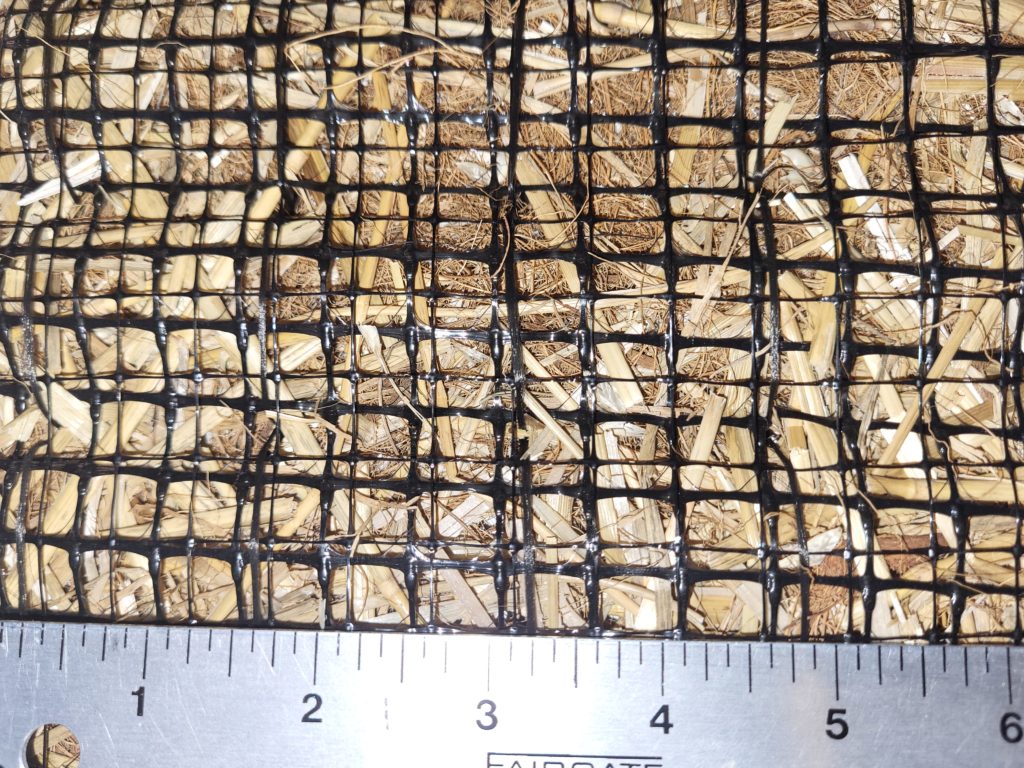

Rolled erosion control products are made from a variety of materials and typically have a matrix fiber for erosion protection and a netting to hold the product together. The RECP selection is based on the product’s performance criteria, which includes percent effectiveness, cover factor, vegetation establishment, functional longevity, and project requirements such as slope gradient and site condition. The matrix is typically composed of straw, coir or wood fiber with a netting made of a biodegradable or plastic netting. Since at least the early 2000s, the industry has recognized the negative publicity of animal entrapments in erosion control blankets and has made adjustments to lessen the impact of the product.

RECP netting is divided into two main categories — plastic netting (Figure 3) and biodegradable fiber netting (Figure 4) — with at least one manufacturer offering a net-free option. The plastic netting is welded with varying opening sizes, often in the range of one-half inch (1.2 cm). It is designed to either be a permanent net or a mesh that is considered degradable, usually though the process of photodegradation. The biodegradable netting is woven from natural products, usually jute or coir. Because the biodegradable netting is woven, the openings are able to move and enlarge as they are pulled.

The matrix material used has been selected based on the slope length and steepness, the length of time it is needed to protect the soil surface and the expected velocity over the surface. The netting choice has often been a consideration of the use after the vegetation has grown. Biodegradable netting can take as long as two years to degrade and can cause issues if the intent is to have a mowed lawn area, where the plastic netting is often photodegradable and can break down within four months.

Newer products on the market have evolved to address the concerns of animal entrapment. The U.S. Fish and Wildlife Service recommends a minimum opening size of 1 inch (2.54 cm). Manufacturers have adjusted their plastic netting to increase the opening or elongate it. Some have used more flexible plastics to allow for some give. Other manufacturers have changed the biodegradable netting to allow it to break down quicker or have developed RECPs that have no netting by incorporating longer fibers that tie together better.

One concern with the limits on the use of RECPs are the turf reinforcement mat (TRM) products. These RECPs are designed to increase the shear strength of the vegetation to allow for the replacement of riprap or other hard armoring, allowing swales and discharges to streams and other water bodies to provide treatment and lessen thermal pollution. A major component of these mats is permanent plastic meshes. These TRMs provide water quality benefits for swale discharging directly to waterbodies and can often reduce the thermal pollution cause by alternative rock lined swales. This suggests that there is still a need for some RECPs with a plastic component or a need to find workable alternatives.

Hydraulically Applied Mulches

An alternative to RECPs may be hydraulic mulches (HMs) and hydraulic erosion control products (HECPs), which are also manufactured from a variety of materials. These HMs and HECPs, conform to similar performance criteria as RECPs: percent effectiveness, cover factor, vegetation establishment, ecotoxicity and functional longevity to align with the project requirements, slope gradient and site condition. Because the concerns with netting and plastics are not a concern with HMs and HECPs, they are a good alternative to RECPs but have tradeoffs as well. The HMs and HECPs are designed specifically for temporary erosion and sediment control and can be specified and installed on slopes up to 1H:1V. However, they are not recommended for channels or areas with concentrated water flow unless used in conjunction with RECPs designed to accommodate the anticipated hydraulic conditions.7 Like RECPs, and for that matter any erosion or sediment control measure, HMs and HECPs need to be specified based on site conditions.

All HMs, HECPs and RECPs require slope interruption devices, typically a wattle or log that will spread the flow down the slope before it concentrates. Hydraulic mulches can include amendments along with seed and fertilizers that correct or improve imbalances within the soil.

Silt Fence and Alternatives

Although, the removal of erosion control measures should be a part of an erosion control plan, they are often left as an afterthought and sometimes, left behind. Silt fence left in place for too long tends to break down and lose its integrity. The result is a very loose open weave that has been known to trap animals. The alternatives include compost socks and straw wattles. Although wattle netting tends to be smaller and has not raised concerns, there is a potential for issues in some jurisdictions and with some endangered species. The compost sock alternative has a finer mess and may be less of a concern, but it may also be denser and not allow for the proper balance of velocity control and spreading of concentrated flow. As an aside, it has been observed that in some areas, straw wattles are an attractive nuisance as the netting has been chewed through and it appears small rodents have attempted to take up residence in the wattles.

What is old is new again. On sensitive sites it may be possible to use alternative materials that have somewhat fallen out of favor. On most construction sites in the Northeast, contractors are either using a hydraulic mulch or an RECP. The use of hay, mulch or straw if weed seeds are a concern could be a good alternate option. Applying a tackifier or crimping the material into the ground eliminates the need for any netting. In addition, the use of natural mulches in some regions can be both a good slope break to replace compost socks and straw wattles or can be used as a mulch cover for temporary protection.

The stormwater industry has been aware of some of the negative effects of various products on wildlife. There have been good attempts to modify products to meet both the site needs and wildlife concerns.

However, as development pushes further into areas with endangered species, the industry will need to be flexible in the design and implementation of practices or will be forced through regulatory requirements, concerned citizens and the court system to find solutions. With an understanding of the wildlife needs, existing practices can be modified to balance the site construction with the wildlife. It doesn’t have to be an either-or scenario.

References

- Barton C, Kinkead K. 2005. Do erosion control and snakes mesh? Journal of Soil and Water Conservation, Volume 60(2): 33A-35A.

- California Coastal Commission. 2012. Wildlife-friendly plastic-free netting in erosion and sediment control products. Water quality fact sheet series. Accessed 16 September 2022.

- Kapfer JM, Paloski RA. 2011. On the threat to snakes of mesh deployed for erosion control and wildlife exclusion. Herpetological Conservation and Biology 6:1-9.

- Minnesota Department of Natural Resources. 2013. Wildlife-friendly erosion control. Accessed 16 Sept 2022.

- Starking, Melissa. 2021. Wildlife-Friendly Erosion Control. U.S. Fish and Wildlife Service. 2021.

- Appeal of Fournier, 2019 WL 6040519, State of New Hampshire Supreme Court.

- Profile Products. 2021. Technical Comparison – Erosion Control Blankets vs. Profile Products Hydraulically-applied Erosion Control Products.

About the Expert

Randall Schuey, CPESC, CWS, CSS, is an environmental project manager and senior scientist at Northpoint Engineering LLC.