Sediment is the number one pollutant of U.S. water resources even though sediment control is commonly required to comply with National Pollution Discharge Elimination System (NPDES) regulations. Sediment-retention devices (SRDs) include silt fence, silt socks, wattles, filter logs, compost and earthen berms and storm inlet protectors. SRDs retain sediment from disturbed land until revegetation and permanent soil stabilization begin without the large area required by settlement ponds.

While each of these SRDs has their own advantages and disadvantages for installation, maintenance and control of sediment, another factor to consider is the amount of waste sent to landfill from used SRDs at the completion of a construction project. Use of a new technology — a Trenchless Curved Silt Fence (TCSF) — reduces landfill disposal by 81% compared to the super silt fence and 98% compared to the 24-inch (61-cm) compost filter sock.

Silt Fences

Silt fences are a popular SRD because the materials are inexpensive and can pool rainwater up to 24 inches (61 cm) or more to allow the accumulated sediment to settle out while slowly filtering the rainwater. A single 100-foot (30.48-m) run of silt fence can hold back 50 tons (45.359 mt) of sediment and water.

A silt fence is composed of a permeable geotextile, such as woven, non-woven and mono-filament plastics, stretched between wooden or metal posts driven into the ground in regular intervals on the downhill side of the silt fence. The geotextile acts as a surface filter so the pores clog quickly to hold the rainwater back while the sediment settles out. In traditional silt fences, the bottom of the geotextile must be trenched (e.g., 6 inches (15.24 cm) wide by 6–8 feet (1.8 to 2.4 m) deep on the uphill side) or static-sliced (e.g., 12-inch (30.48 cm) deep slit) into the ground to prevent rainwater from running underneath. Both trenching and static slicing are affected by roots and rocks below the ground surface, as well as terrain contours or property lines, and require ground compaction afterward to prevent rainwater from eroding the trench.

A wire or chain-link fence can be placed behind the geotextile to reduce stretching due to hydrostatic pressure. When backed by chain-link, this system is referred to as super silt fence, which may double the cost of the silt fence installation and entails disposing of more material in a landfill when removed. Compared to traditional silt fence and super silt fence, the TCSF is more resistant to poor installation techniques since trenching and compaction are not needed. The TCSF also has reusable stakes and sand tubes that reduce future installation costs and the amount of material sent to the landfill.

Compost Filter Socks

Another popular SRD to achieve 15 to 26 inches (38.1 to 66 cm) of ponding is compost filter socks held in place with wooden stakes driven through the top of the tube into the ground below. The compost- and wood-chip-filled versions are extremely heavy to transport for installation and removal, so larger diameter socks are filled at the construction location. This process requires numerous truckloads of compost or a nearby source of woodchips. If approved by the landowner, compost socks can be cut open when no longer needed so that only the fabric tube is sent to the landfill. The woodchip socks, however, are acidic and inhibit revegetation when cut open so they either need to be removed or the woodchips must be neutralized into the soil. Compared to compost filter socks, the TCSF uses less raw material with lower associated transportation and landfill costs. The disposal weight of a 28-inch (71-cm) TCSF is 0.5 lbs./ft (0.677 J) compared to 80 lbs./ft (108.5 J) for a 32-inch (81.28-cm) compost sock.

Trenchless Curved Silt Fence

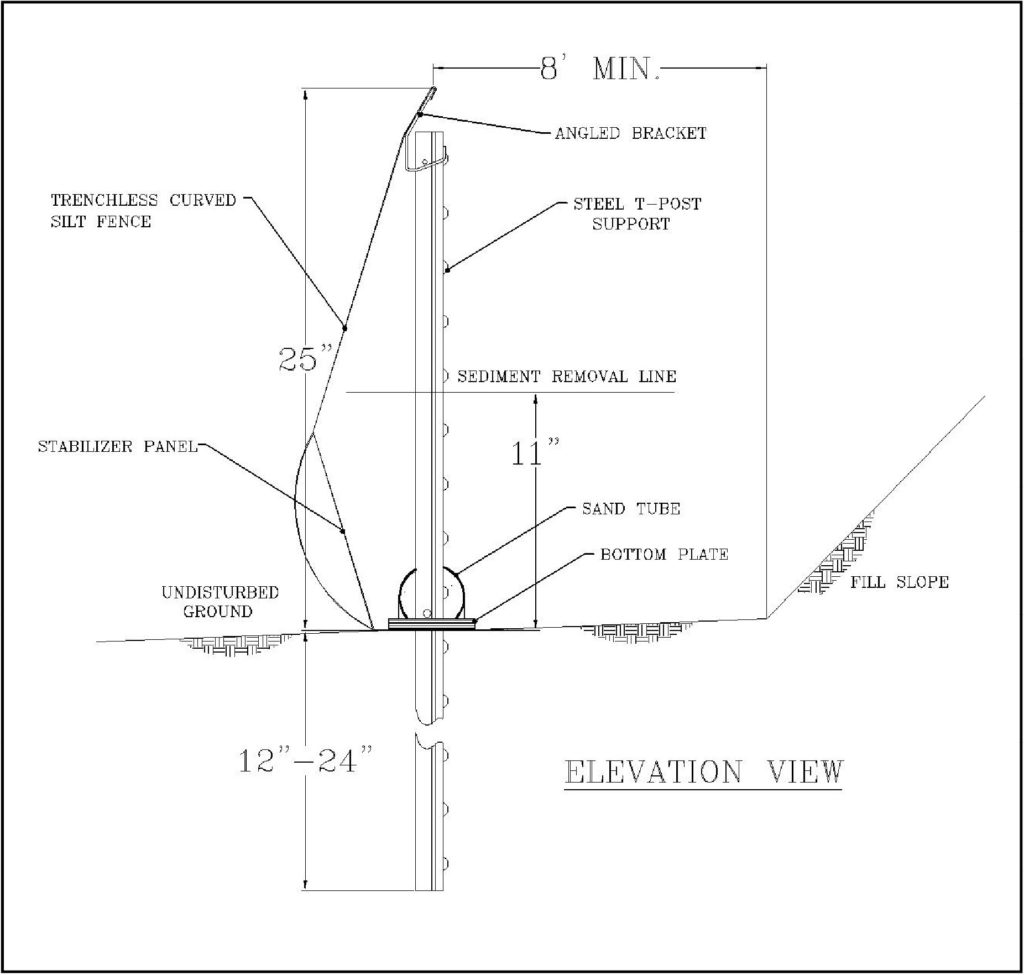

The Trenchless Curved Silt Fence (Figures 1 and 2) overcomes the tipping and trenching disadvantages of silt fence and the weight and volume disadvantages of compost sock while providing up to a 55% reduction in materials, installation and removal costs compared to 24-inch (61-cm) compost filter sock and up to a 40% reduction compared to super silt fence.

The patented design includes a sand tube ground seal and a curved cross-section. The sand tubes, which eliminate trenching, slide into a bottom pocket to seal the base of the fence to ground while t-posts and ground plates anchor the system in place (Figure 3). The sand tubes are covered in hydrophobic scrim that resists absorbing water, to prevent water logging and freezing, both while in storage and in use. The woven inner layer of the sand tube provides durability and resistance to drops, punctures and tears. The first flush of sediment-laden rainwater provides a second seal to the ground as it flows over the ground plates and behind the sand tubes.

The TCSF is constructed with two plies of woven slit-film geotextiles ultrasonically bonded together. The 32.4 gpm/sf geotextile (grey) is used on the fill slope side with the AASHTO M-266, NTPEP-tested, 16.4 gpm/sf geotextile (black) behind. The two-ply construction is substantially stronger and exceeds AASHTO M-288 unsupported silt fence fabric tensile, tear, burst and puncture resistance. The two-ply construction replaces the need for wire or fence reinforcement and has a soil retention effectiveness of 94.26% and seepage effectiveness of 91.07% (ASTM D-7351).

The two-ply construction also provides a filtering efficiency of 96.3% with an increased slurry flow rate slurry flow rate of 0.464 gpm/sf (ASTM 5141), which is 55% greater than the 0.3 gpm/sf requirement for traditional silt fence and super silt fence. The increased slurry flow rate and increased filter area per effective height (curved cross-section) enbles the TCSF to handle rainfall on slopes that would normally require super silt fence. An addional benefit of the TCSF is a 29%–43% reduction in ponding volume behind the silt fence to reduce area flooding.

Unlike traditional silt fence and super silt fence that rely on the stakes to resist tipping over, the TCSF has a curved cross-section beyond the t-post to transfer hydraulic force into ground. The curved cross-section is obtained by ultrasonically welding two woven polypropylene fabrics together and shortening the up-slope fabric to maintain a curve under hydrostatic pressure. This dam design of decreasing radii increases tipping stability by 380% compared to 33-inch-high super silt fence. The onion shape uses the water weight behind the stake as part of a dam wall to reduce the tipping force on the post.

Trenchless installation benefits include:

Undisturbed surrounding soil during installation and removal.

- Year-round installation in frozen, wet, compacted or rocky soils.

- Low impact on tree root structures.

- No heavy machinery for trenching, static slicing and post-hole digging.

- Easily installed on steep slopes, wetlands and hard terrain.

The TCSF has been approved as an alternative BMP by the Pennsylvania Department of Environmental Protection. As the focus on environmental protections grow, the importance of looking “downstream” to enhance control of sediment, minimize increasing weight in landfills, improve the ease of installation of SRDs and manage costs increases the importance of continued innovation in all products used in the sediment and erosion control field.

More Information

Testing results, references and more product information about the Trenchless Curved Silt Fence can be obtained at newpigenergy.com/products/trenchless-curved-silt-fence or by calling 855.744.5463.

About the Expert

Beth Powell is president of Fluid Conservation Systems and previously served as president of New Pig Energy.