By Dwayne Stenlund, MS, CPESC, MnDOT

It is clear from predictive models and field experience that the majority of sediments are lost in the wettest months at the height of typical full speed construction activity. In Minnesota, about 70% of all erosion that can occur happens in the months of June, July and August. Winter months may provide around 5% of sediment release, with spring and fall about equally divided for the remainder.

Although the percentage of sediment release is lower, erosion prevention or sediment yield models do not account for the energy released when snow melts rapidly. While some moisture from rain/snow fall might be abstracted into the soil profile and remain in place, almost five months of rainfall accumulations may be released in two weeks. The volume and rate of discharge can mimic a 100-year storm event.

No two snow melt event years are the same nor can it easily be predicted before it occurs, so all soils not actively worked should be kept in a perpetual stabilized conditions, concurrent with the work.

The EPA Construction General Permit (CGP) and southern states with delegated National Pollutant Discharge Elimination System (NPDES) authority are typically silent for stabilization requirements and snow cover, but surprisingly northern states are also commonly silent for stabilization of exposed soils under frozen winter conditions. While it is reasonable to assume that frozen soils will not erode and common best management practices (BMPs) are not feasible under such conditions, the gap in understanding and requirements misses the point.

Due to shortened construction created by the onset of the winter season, or public costs associated with delays from winter, construction that includes grading and structures now continues every month. While there may be less open soil grading due to costs of working frozen and icy soils, it still occurs. Due to many factors, cold climate construction is here to stay. Design must remain compliant to all seasons.

NPDES CGP regulations amended by the Minnesota state delegated authority (MPCA) to fit state conditions does not recognize frozen soil conditions as a reason to stop concurrent stabilization practices or as a reason to not stabilize all exposed soils in a timely manner. For routine exposed soils (not special or impaired), 14 days is the maximum delay for stabilization events of soils not actively worked. Note the definition of 14 days includes the words “stabilized immediately,” starting the day when work stops and must be completed within 14 days.

Prevent Erosion at Planning Stage

Preservation of green space through design offers the best winter erosion prevention for the least cost. Incomplete and inaccurate Stormwater Pollution Prevention Plans (SWPPPs) do not generate the least cost bids. In my opinion, the owner’s plan must reflect at least one means and method program that delivers all public and natural environmental commitments as described within the contract language. The actual low bid submitted by the contractor must be the least cost bid capable of delivering the commitments and contract. This may mean that work in winter may be the least cost option.

Winter work is also beneficial in areas with endangered or sensitive wildlife or for projects to restore wetlands or re-meander streams. Phased design and contract implementation can also utilize frozen ground conditions, such as ice roads, haul roads and wetland access, to avoid impact on the environment. Time of year is an erosion prevention BMP that also reduces costs by reducing timber pads and other soft soil crossing technologies.

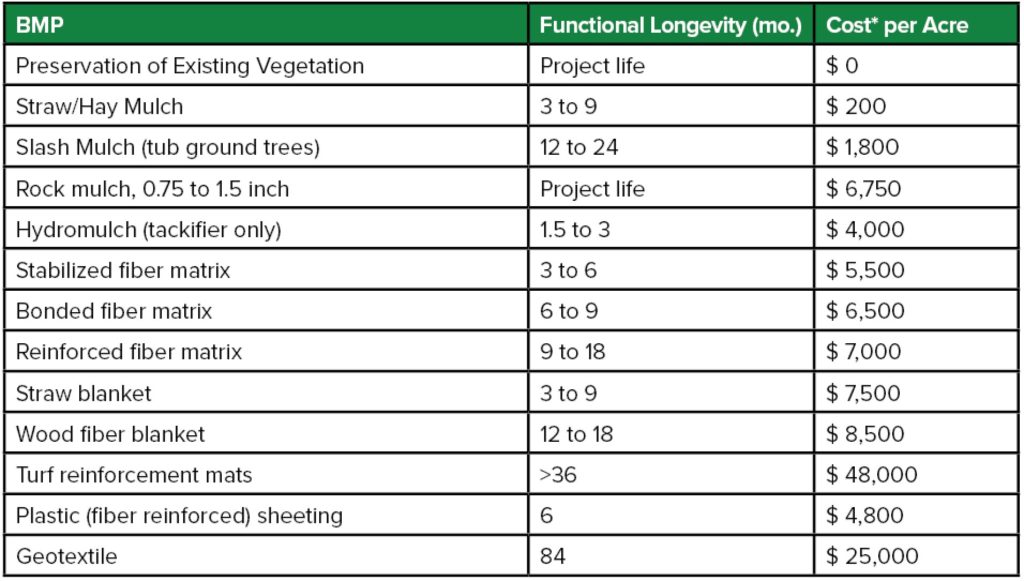

All BMP must be designed with functional longevity, or effective service life, considerations. It makes no economic and implementation sense if the erosion prevention BMP selection, while lower cost, does not last long enough to perform as intended. BMPs that do not last through the winter and spring runoff do not reflect proper design, nor reflect the true cost of a BMP if it must be reinstalled or supplemented again.

Table 1 provides guidance for functional longevity of each type of erosion prevention BMPs. Functional longevity is based on my engineering judgment and field experienced in Minnesota, as there are no ASTM test methods available. A significant functional longevity decline and loss of expected performance occurs when 10% of the material has been compromised. Typically, the contactor is not required (forced) to supplement or replace the erosion prevention BMP until the BMP has lost 25% of material integrity. Note that vegetation does not grow in winter to replace the functional loss of organic mulch materials. Different states will have clear differences in weather and decomposition rates of organic and synthetic materials used for temporary erosion prevention.

Erosion Prevention BMPs

*Costs have been calculated on a per acre basis for comparison from annual bid units of installed prices submitted by contractors and project owner engineer’s estimates. Note that unit prices submitted by contractors do not necessarily reflect reality in a low bid system nor do they follow defined application rates.

- Snow Mulching

Snow mulching is the process of applying an agricultural grain straw or forage hay over the snow, which is the lowest cost of any winter BMP for erosion prevention. Application in winter allows access on nearly all soil types and typically steeper slopes than recommended other times of year—3:1 and flatter.

The winter design rate is 80% of normal soil coverage, with normal defined as 90% soil cover and estimated for payment as two tons per acre. The mulch must be applied at a lower rate than normal to allow light penetration that differentially warms the mulch to melt and freeze into the snow pack. Timing of mulch application by the contractor is allowed to sometimes extend beyond 14 days to coincide with a predicted snow event as this forms what I call a “mulch sandwich layer.” Mulch moves vertically downward within the snow pack as the snow melts and is heavy enough when saturated to remain in place over wet spring and mucky soils and continues to protect soils during spring rain events. Application on frozen ground without snow cover typically requires an additional application of water or hydromulch to freeze bond in place to prevent wind loss.

- Winter Hydromulching

Any hydraulic mulch that is applied over wet or frozen ground must have a chemical makeup that accounts for proper curing and bonding to soil during these conditions. There is only one suitable hydraulically applied mulch over frozen or wet ground that is approved by Minnesota Department of Transportation (MnDOT). The industry-defined highest end product works if applied on frozen, but not snow-covered, soil. If applied on snow, no soil bonding occurs, and creates a nuisance runoff condition that now includes all the chemicals and organic fibers in the original product.

Design defined application rate as per manufacture for slope length and steepness, but not less than 3,500 pounds per acre. If snow is present, the contractor is required to first remove snow, which is hauled to sediment traps for melt control, prior to application. Hydromulch applications are common in winter and are tightly scheduled and risk managed to account for predicted storm events. Hydromulch coverage winter option provides the greatest range of soil lengths and steepness benefits at the greatest functional longevity best value until the soils are again dry enough to be workable.

- Winter Rolled Erosion Prevention Products

Rolled erosion prevention product (REPP) go by many names that include blankets and mats. MnDOT uses REPP to define any erosion prevention system that comes in a roll, including straw through polymer concrete. REPPs work best when properly anchored to soil, but there is no limitation that prevents installation in any winter condition including blizzards, but perhaps not snow squalls and mega-events, except depth of snow cover. In general, all temporary applications of REPPs must have snow depths less than 2 inches, with removal of snow excess by any suitable method. Anchoring methods change with the REPP category by winter months and soil type. Typically a washer on a nail is used in winter because U-pins normally used cannot penetrate frozen soil.

Designers continue to specify winter blanket using the same factors for any ‘normal’ time of year. While the material application details remain the same, a special provision is necessary to describe the change in anchoring method for winter. Additional anchoring methods include freezing in place with water or hydromulch overtopping.

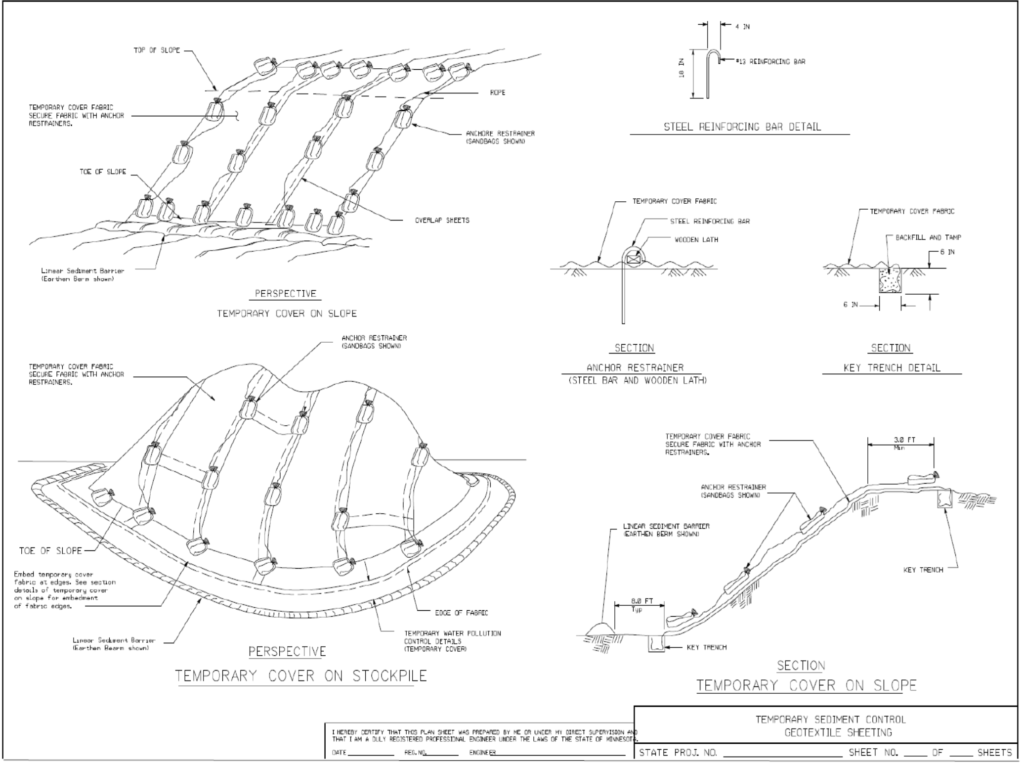

Plastic and geotextile exposed soil covers represent the highest level of REPP performance. The anchoring is much more robust with head trenches and sand bags attached to ropes. The best implementation detail comes from California Department of Transportation but has been modified to reflect a regular MnDOT detail sheet (see Figure 1).

- Winter Rock

There are no limits to the imagination for stabilizing and protection exposed soils, regardless of weather or time of year. While rock aggregate can also be used for creating sediment control perimeter and check features, it also makes excellent winter stabilization erosion prevention.Rock can be configured to stabilize openings in perimeter sediment controls and stabilize ditches. If the rock is used for exits, a geotextile liner must be used to prevent soil pumping when soils thaw. Otherwise, rock placed by any means for exposed soil stabilization is acceptable.

Design thickness is two to four inches, where the depth of placed rock aggregates is a function of average diameter size that may range from 3/8-inch pea gravel to 3-inch crushed ballast. In general, depth is 1.5x of aggregate diameter, but not less than 1-inch thickness. Assume 1 cubic yard will cover 18 square yards at a 2-inch depth. The best way to determine cost is to convert the cubic yards into tons for the area to be covered. Paying for aggregate and placement by the ton eliminates debate about placed depth of rock that is pushed into ice, mud and snow.

- Dormant Seeding

While technically not a winter stabilization practice, nearly all native and non-native temporary seed mixtures typically specified by state agencies can be dormant seeded. Some temporary seed mixture components like oats do not tolerate cold and wet soil conditions and easily decompose before ever breaking dormancy for germination. Because most temporary seed mixtures are relatively inexpensive, I recommend seeding along with winter stabilization measures that are composed of organic materials. Do not fertilize over frozen soils or on top of snow. The resulting nutrient rich runoff is unacceptable to any water of the state. If it is determined by later inspections that the resulting seedlings look yellow, light green or stunted, a foliar (liquid) application can be made using a hydroseeder type machine.

Routine Inspections Required

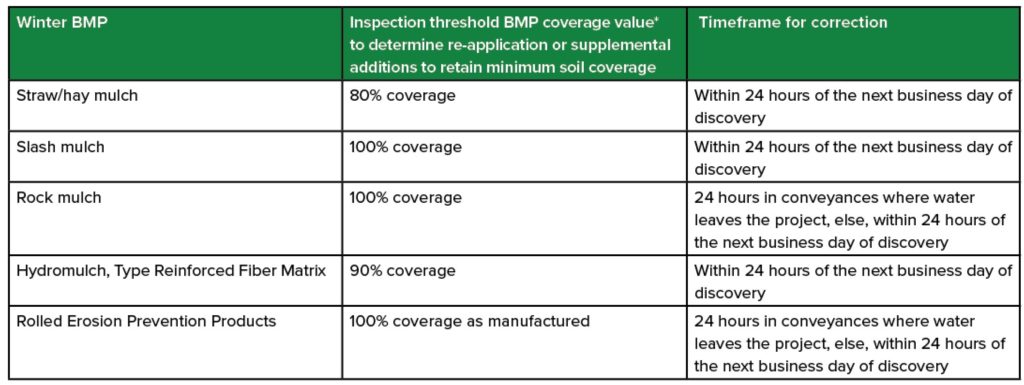

All installed erosion prevention BMPs must be routinely inspected for effectiveness and integrity or when runoff resumes. All noted deficiencies must be corrected within defined timeframes. In Minnesota, all corrective actions must occur within 24 hours of the next business day of discovery. The following table lists criteria for determining when corrective actions or rework schedule are required.

*Visual inspection determines when coverage is less than the minimum listed. A 100% value means the installed BMP must be kept at 100% to be considered in a proper functional condition for permit and contract compliance.

Conclusion

Permit compliance is year-round activity. The EPA CGP is a general permit that attempts to list required conditions for all authorized and delegated states, recognizing that local and regional conditions will not equally apply everywhere. It does not take into account deleterious changes in climate variations that exacerbate ability to keep BMPs in a functional condition. Cold climate states with cold climate experienced contractors must design, select, install, maintain and continually adapt to change with winter appropriate erosion prevention measures. While work in winter is slower and typically more expensive than work performed in the warm months, nothing is impossible when everyone works together. This starts with great design and clear expectations.

About the Author

Dwayne Stenlund, M.S., CPESC, is the coordinator for the Natural Resource Program in the Office of Environmental Stewardship, Erosion Control and Stormwater Management Engineering Unit for the Minnesota Department of Transportation.

Resources

An example PDF reference document for winter stabilization BMPs can be found at:

Stenlund, Dwayne, 2015. https://fairmont.org/wp-content/uploads/2018/03/WinterGuidanceMnDOT.pdf. Minnesota Department of Transportation, Office of Environmental Stewardship, Saint Paul, Minnesota.

Additional information can be found at:

https://stormwater.pca.state.mn.us/index.php?title=Winter_construction_practices_for_site_stabilization,_erosion_prevention_and_sediment_control

https://www.dot.state.mn.us/environment/erosion/pdf/winter-npdes-inspection-requirements.pdf

https://www.dot.state.mn.us/environment/erosion/pdf/field-guide-bridge-construction.pdf