By Julie Morelli, P.G., REM, CPESC

The National Pollutant Discharge Elimination System (NPDES) program provides a regulatory framework to authorize the discharge of stormwater from regulated activities such as construction, industry and urban environments. Industrial sites identified by standard industrial classification (SIC) codes or industrial activity (IA) codes listed in the NPDES Multi-Sector General Permit (MSGP) are subject to permit and compliance obligations associated with industry specific pollutant sources located outside at an industrial site.

The MSGP is a different permit than the construction stormwater general permit, and typically will not authorize stormwater from construction sites. The purpose of the MSGP is to target the elimination of pollution in stormwater runoff associated with industrial site activities occurring outdoors. Best management practices (BMPs) are established and captured within a stormwater pollution prevention plan (SWPPP) which becomes the guide for required actions to maintain permit compliance and minimize pollutants in stormwater runoff.

There are many important factors that must be included in the development of an effective industrial SWPPP. However, the best written SWPPP in the world will not manage stormwater runoff if it is left on the shelf.

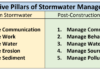

Permits and planning documents provide the foundation for implementation. Every great stormwater program includes five key elements: inspections, monitoring, recordkeeping, reporting and training. By adhering to these components, an industrial facility can achieve improved NPDES compliance and runoff water quality.

(1) Inspections

Inspections, both routine and periodic, are mandated by the NPDES MSGP and corresponding state permits. The frequency and content of inspections and associated records are dictated by permit conditions. Typically, inspections must be performed monthly or quarterly and once per year when a comprehensive site compliance evaluation is stipulated.

Inspections should be performed by “qualified” personnel who are familiar with the site and knowledgeable of the SWPPP and applicable stormwater regulations. Some jurisdictions mandate a “certified” inspector.

Facilities should use inspection reports to document good-faith efforts to manage operations in accordance with the SWPPP and address common issues. The inspection is the beginning of a continuous improvement process. Then, if a problem is identified, a corrective action is requested.

A follow-up inspection verifies the completion of the assigned corrective action and assesses the effectiveness of the solution. Recording observations and requesting corrective actions on an inspection report is required, but that is not enough to affect change. The corrective actions and expected results need to be assigned to an accountable person to improve site conditions.

(2) Monitoring

Monitoring defines the qualitative and quantitative observations of stormwater runoff from the discharge points at an industrial facility. Stormwater monitoring should capture the “first-flush” of runoff, meaning runoff that occurs within the first 30 minutes of discharge from a qualifying rain event. The frequency, methods and reporting of monitoring data are dictated by permit conditions. Additional monitoring criteria may apply due to local ordinances, discharges into impaired or exceptional waters, or a result of a stream’s Total Maximum Daily Load (TMDL) Implementation Plan (I-Plan).

Basic monitoring requirements established by the MSGP include:

- Quarterly Visual Monitoring

A qualitative analysis of stormwater quality. As implied by the name, visual monitoring must be completed quarterly each calendar year during the permit term. Monitoring must be conducted during the normal hours of operation for the facility and samples must be collected in a clean, clear, glass or plastic container and examined in a well-lit area. Recorded observations should comply with the criteria listed in the permit and typically include aspects such as color, odor, foam, sheen, and floating, settled or suspended objects.

- Benchmark Monitoring

A quantitative analysis of stormwater quality. Parameters are driven by the industrial sector applicable to the facility and are representative of typical pollutants associated with industrial activities. Benchmark parameters may vary within a sector by the listed standard industrial classification (SIC) code or industrial activity (IA) code that describes facility operations.

Monitoring frequency is permit-driven and is typically semi-annual or quarterly. An exceedance of a benchmark value is not a violation of the permit. However, the facility must investigate and take corrective actions taken to reduce the concentration of the pollutant during the next discharge event.

- Categorical Numeric Effluent Limitation (CNEL) Monitoring

Monitoring is required of specific SIC or IA codes within certain industry sectors. CNELs are quantitative in nature and reflect national water quality standards for specific industry types as codified in federal regulations and listed in the NPDES permit. Similar outfalls may not be used to reduce CNEL monitoring. A violation of a CNEL threshold is considered a violation of the permit and must be self-reported.

(3) Recordkeeping

Recordkeeping is documentation that is maintained onsite and used to demonstrate compliance with permit requirements. Records should be kept with the SWPPP or readily accessible to regulators with jurisdiction over stormwater discharges from the facility.

Successful recordkeeping requires that facilities know what activities must be recorded, the content required by the permit and the record retention policies associated with the permit.

The EPA MSGP provides the basis for recordkeeping, though some variations occur between states. The list below provides a basic guide to which records are likely to be required as inclusions for the SWPPP:

- Management certification of the SWPPP

- Delegation of signatory authority

- Agency permits, correspondences, etc.

- Rain gauge

- Inspection records

- Training records

- Preventive maintenance logs

- Logs of spills and leaks

- Qualitative and quantitative

- monitoring records

- Training and education materials

Electronic systems are commonly used to manage stormwater records. Make sure the records contain information required by the permit and are readily available during a regulatory inspection.

(4) Training

EPA and state MSGPs require training programs be prepared and implemented annually for all employees who are responsible for implementing and maintaining activities in the SWPPP and/or those who work in areas where industrial materials are exposed to stormwater. Training generally requires tasks such as proper material management and good housekeeping, spill prevention and response, spill reporting and familiarization with both BMPs and the goals of the SWPPP.

Facilities must also provide basic education to all employees, even if they are not directly responsible for the SWPPP. This should include the stormwater pollution prevention goals, who is on the SWPPP team, and how to contact them if a stormwater issue arises.

(5) Reporting

Reporting is the documentation that must be submitted to the regulatory agency for compliance with a permit condition. Not all records must be reported. Each permit defines the reporting requirements and there are a number of reporting variations among the NPDES MSGP state permits. Generally, reporting will include the following minimum reports:

- Delegation of signatory authority

- Benchmark monitoring report form

- Annual reports

Customize Your Industrial Stormwater Program

Stormwater management is a program that must be designed for site-specific conditions, permit compliance and industrial activities. A SWPPP provides a basis for actions, but it can be overwhelming to implement. Breaking up SWPPP implementation into its five basic elements provides a key to successful stormwater compliance. Assignment of action items to accountable members on site will improve compliance and provide measurable benefits to stormwater quality

About the Expert

Julie Morelli, P.G., REM, CPESC, has deep and diverse experience in both public and private environmental compliance with expertise in water quality, erosion and sediment controls, solid waste management, spill delineation, Phase I/II/III environmental site assessments and corrective action programs. She develops integrated compliance programs encompassing requirements from U.S. Environmental Protection Agency, the U.S. Coast Guard, the U.S. Army Corps of Engineers and the U.S. Fish and Wildlife Service.